Researchers from Greece and France, in their latest article published in the journal Energies, have studied the influence of rotor bar shapes to increase the efficiency of a single-phase induction motor.

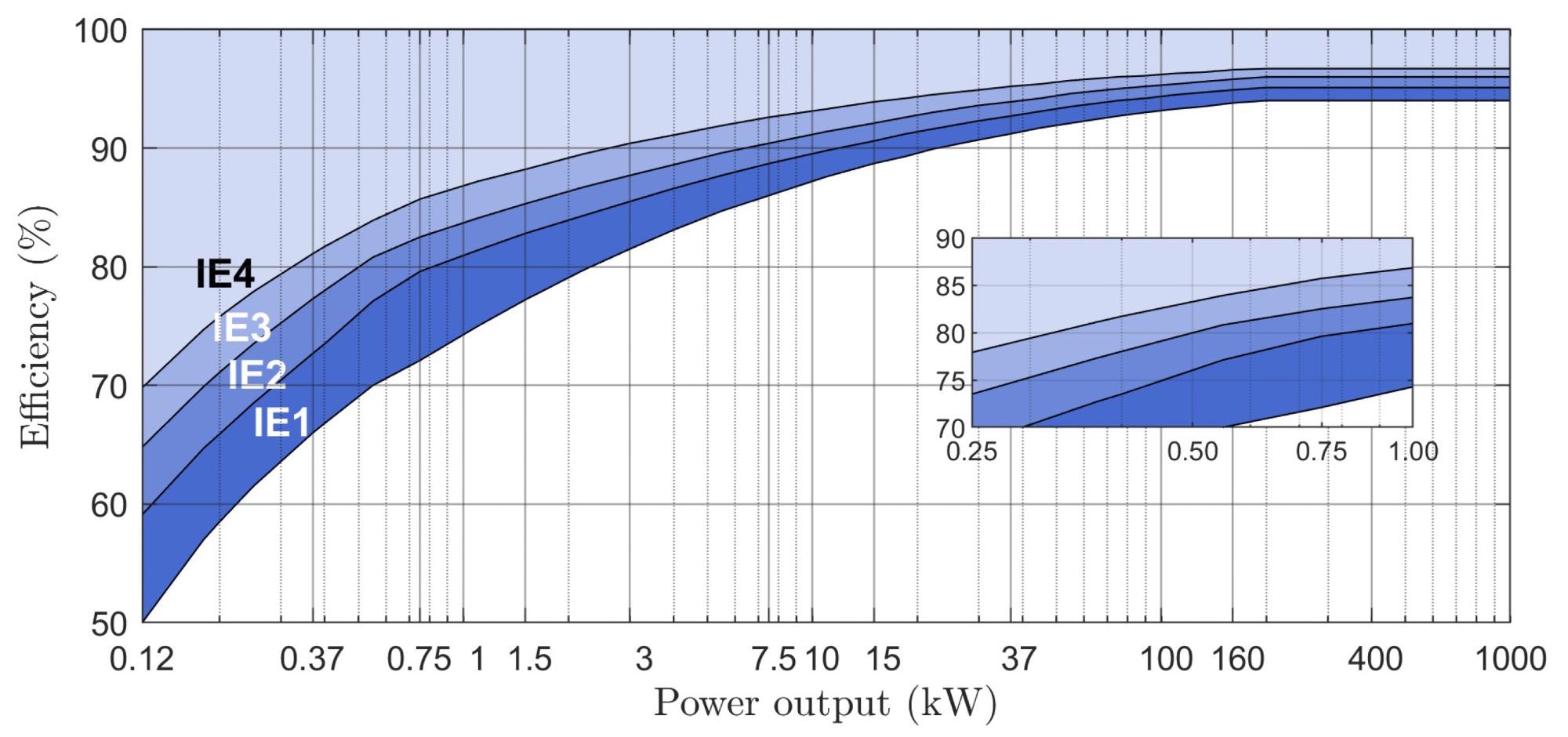

Worldwide, obligatory requirements for the effectiveness of line-operated electrical motors have been established. Compact single-phase induction motors (SPIMs) will not be spared in terms of effectiveness and efficiency, as new restrictions are set to be implemented no later than July 2023. As a result, the efficiency of capacitor-run SPIMs will be required to exceed (now) normal values and meet the standards of the IE3 (i.e., premium) performance class. Less consideration has been given to the influence of rotors bar form on SPIM performance and starting capabilities. This area was covered in this paper by investigating rotor squirrel-cage layouts with eight distinct bar forms.

International efficiency classes for four-pole IMs at 50 Hz. Image Credit: Chasiotis, I.D et al., Energies

Single-phase induction motors (SPIMs) account for a sizable portion of the worldwide electric machines industry due to their widespread use in a variety of products (e.g., cutting tools, pressurized cleaning technology, rotating belts, latest efficient washing machines, commercial grinders, food storage facilities, food mixers, microwave ovens, conditioning units, thermal circulation pumps, fans, centrifugal pumps, etc.). Their rated output power ranges from a few kilowatts to a few hundred kilowatts, and they are available in a variety of designs depending on the mechanism used to make them self-starting motors.

They are available in five varieties: (a) split-phase, (b) shaded poles, (c) capacitor-start/induction-run, (d) capacitor-start/capacitor-run, and (e) capacitor-run SPIMs. Because the transmitted single-phase current generates only a pulsing electromagnetic field, the beginning mechanism is required.

This motor's construction is quite identical to that of a three-phase squirrel-cage induction motor (IM). The fundamental distinction is in the configuration of the stator's primary and supplementary windings. These coils are 90 electrical degrees phase-shifted vertically. During both the initiating and operating operations of the motor, a fixed capacitor is linked in series with the secondary coil.

The stator and rotor core of the SPIM are composed of thin laminae of electrical metals. The squirrel-cage of the rotor is manufactured of a conducting alloy by die casting. Because of its inexpensive cost, aluminum alloy is more commonly used in the fabrication of tiny SPIMs, and it provides for greater freedom in the design of the bar.

Several configurations of semi-closed, closed, or open slots have been presented for the rotor bar design to determine which one advantages the motor's performance parameters. Based on the National Electrical Manufacturers Association's guidelines, the bar designs are categorized into four categories (design classes). Each of these results in a unique torque–slip profile for the motors and has a significant impact on the machine's operating efficiency and launching capabilities.

To date, research studies have focused on the emergence of more precise magnetic and thermal models for better assessment of the motor's electromagnetic and thermal behavior, the optimized rotor squirrel cage configuration, the appropriate choice of the rotor bars/stator slots conjunction, and the establishment of innovative casting processes as well as novel materials for cores and squirrel cags.

Because the majority of the aforementioned solutions are not easily adaptable to large-scale production, it is critical to have design techniques that cause minor alterations to the pre-existing SPIMs manufacturing stage.

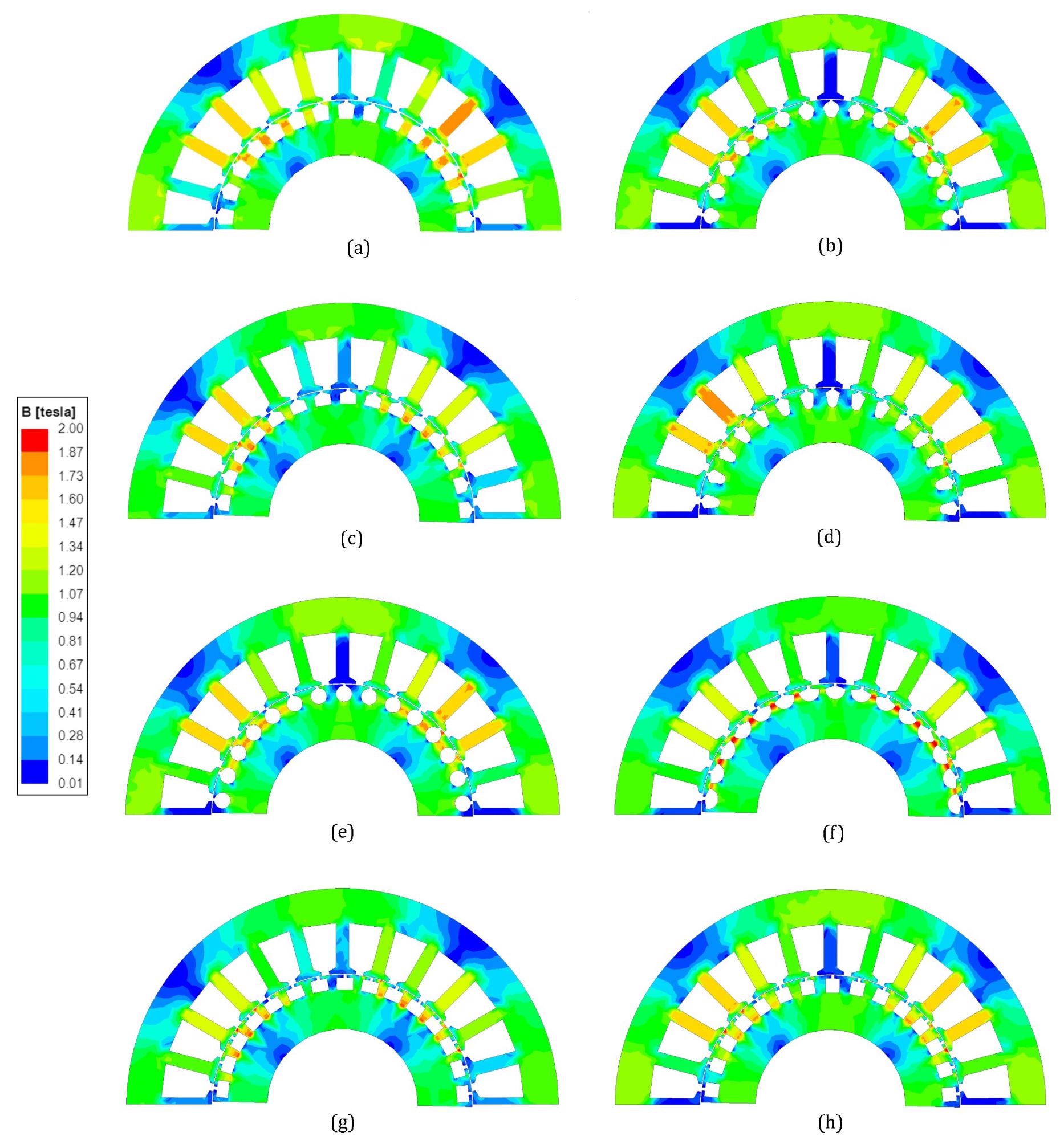

View (½) part and magnetic flux density distribution under nominal operation of the SPIM with Crun = 18 μF and rotor bars of: (a) trapezoidal, (b) oval, (c) pent, (d) polygonical, (e) round, (f) drop, (g) rectangular, and (h) quadrangular shape. Image Credit: Chasiotis, I.D et al., Energies

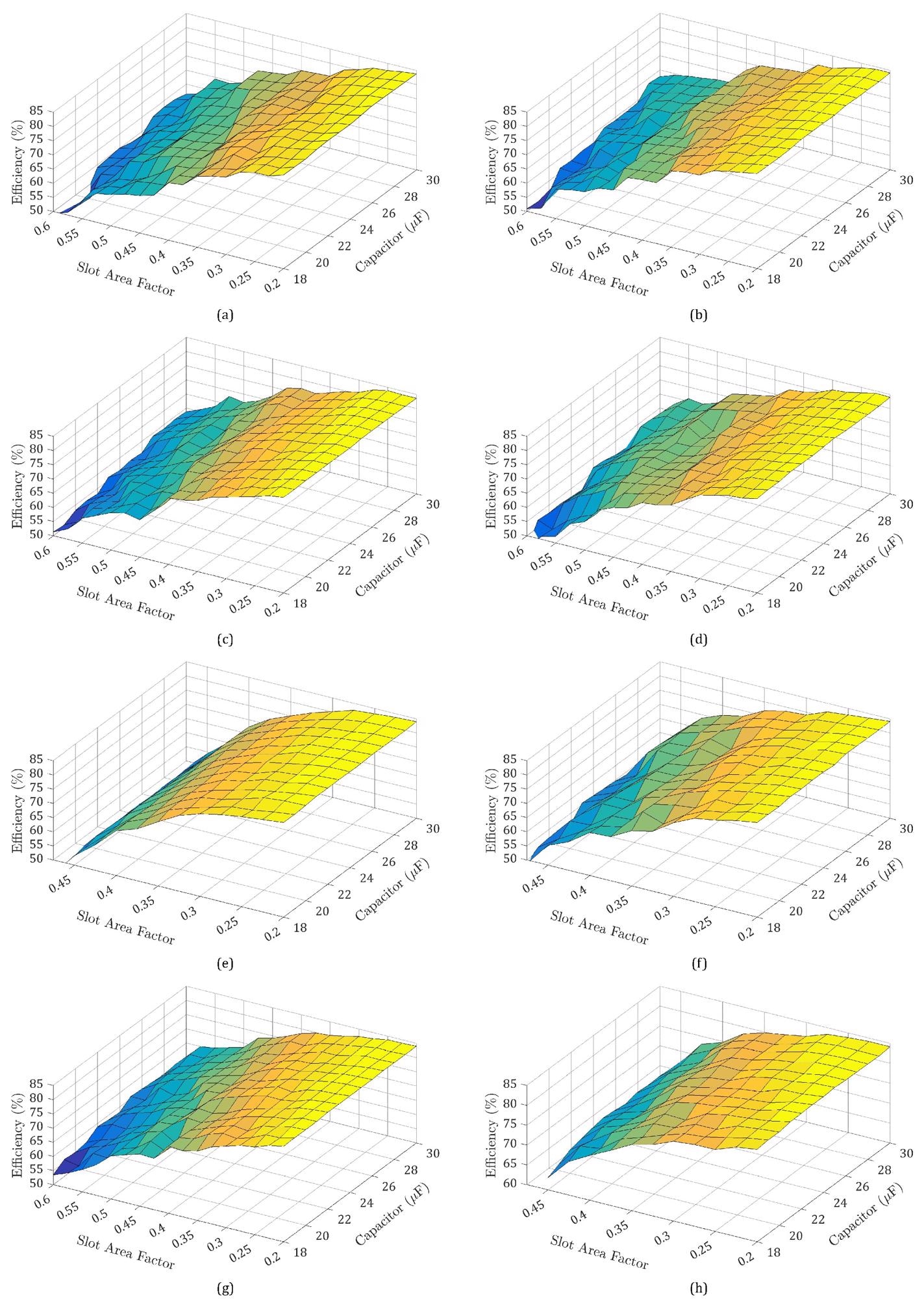

The influence of the rotor bar shape on the efficiency of the capacitor-run SPIM was examined and given in the study. The results showed that the design of the bar had a significant impact on the particular performance parameter. The gap between the lowest and maximal efficiency values of the best-performing SPIMs was 0.42 percent.

The discrepancy between the lowest and greatest efficiency values of the SPIMs with varying rotor bar shapes for a given capacitance ranged from 0.31 percent to 0.98 percent. It was pointed out that the bar shape had a significant impact on various operational features such as beginning current, failure torque, current shift inclination, electromagnetic saturation, and so on. As a consequence of the quantitative evaluation of the obtained SPIMs and the discussion of results, beneficial conclusions were formed.

To summarize, the study sheds light on the creation of capacitor-run SPIMs with improved efficiency, while also addressing issues such as the influence of contact resistance on rotor ohmic losses and the impact of capacitance on the motor's magnetizing inductance.